Beginning the Grate

I had planned to build the actual grill body first, but we were low on sheet steel, so I have to wait until next week. Same with 1-1/4" square pipe for the frame. So I decided to start off building the grate.

I can't remember the name of this tool, but it sure can bend 1/4" rod.

I can't remember the name of this tool, but it sure can bend 1/4" rod.

Unfortunately, it's a bit hard to figure out exactly where the bend will come out... I made one side about half an inch too long.

Unfortunately, it's a bit hard to figure out exactly where the bend will come out... I made one side about half an inch too long.

Straightening it out to try the bend again. Thanks, vise!

Straightening it out to try the bend again. Thanks, vise!

There we go.

There we go.

I welded and ground the gap. It's not the most beautiful joint ever, but it'll get the job done. Now I've got to cut loads of 17-inch rods to make the cooking surface.

I welded and ground the gap. It's not the most beautiful joint ever, but it'll get the job done. Now I've got to cut loads of 17-inch rods to make the cooking surface.

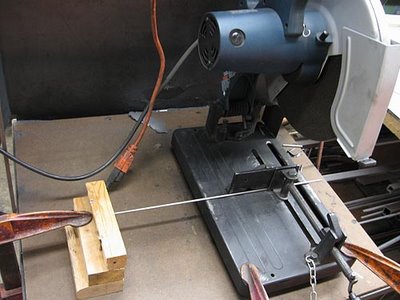

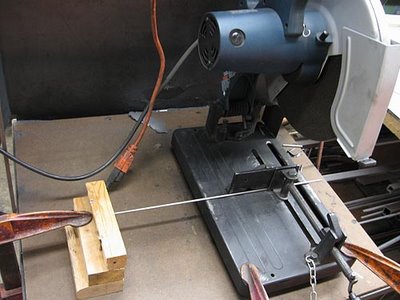

I improvised a jig to stop the rod at the correct length, so I can cut them all without measuring every time. The abrasive disc chop saw is not the most elegant tool- it leaves a rough edge and throws off tons of hot sparks. On the other hand, it's a lot faster than a band saw or bolt cutters. I measured the rods a quarter-inch too long, so I can get them down to exactly equal length with the grinder.

I improvised a jig to stop the rod at the correct length, so I can cut them all without measuring every time. The abrasive disc chop saw is not the most elegant tool- it leaves a rough edge and throws off tons of hot sparks. On the other hand, it's a lot faster than a band saw or bolt cutters. I measured the rods a quarter-inch too long, so I can get them down to exactly equal length with the grinder.

Awww yeah.

Awww yeah.

That was it for my shop time on Saturday. I was hoping to get the whole grate welded together, but I will have to finish it next time. After I put these rods on, I will make some handles for it and then move on to the grill body.

I can't remember the name of this tool, but it sure can bend 1/4" rod.

I can't remember the name of this tool, but it sure can bend 1/4" rod. Unfortunately, it's a bit hard to figure out exactly where the bend will come out... I made one side about half an inch too long.

Unfortunately, it's a bit hard to figure out exactly where the bend will come out... I made one side about half an inch too long. Straightening it out to try the bend again. Thanks, vise!

Straightening it out to try the bend again. Thanks, vise! There we go.

There we go. I welded and ground the gap. It's not the most beautiful joint ever, but it'll get the job done. Now I've got to cut loads of 17-inch rods to make the cooking surface.

I welded and ground the gap. It's not the most beautiful joint ever, but it'll get the job done. Now I've got to cut loads of 17-inch rods to make the cooking surface. I improvised a jig to stop the rod at the correct length, so I can cut them all without measuring every time. The abrasive disc chop saw is not the most elegant tool- it leaves a rough edge and throws off tons of hot sparks. On the other hand, it's a lot faster than a band saw or bolt cutters. I measured the rods a quarter-inch too long, so I can get them down to exactly equal length with the grinder.

I improvised a jig to stop the rod at the correct length, so I can cut them all without measuring every time. The abrasive disc chop saw is not the most elegant tool- it leaves a rough edge and throws off tons of hot sparks. On the other hand, it's a lot faster than a band saw or bolt cutters. I measured the rods a quarter-inch too long, so I can get them down to exactly equal length with the grinder. Awww yeah.

Awww yeah.That was it for my shop time on Saturday. I was hoping to get the whole grate welded together, but I will have to finish it next time. After I put these rods on, I will make some handles for it and then move on to the grill body.

2 Comments:

That was a nifty bit of work straightening out the frame and re-bending it. Does a "do-over" like that have any consequence on the strength of the metal afterwards?

Why does grinding off the lengths of rod take less time than using a bolt cutter?

It probably makes it a little bit more brittle, but it's inconsequential because this isn't a load bearing piece. I could fix it with tempering (heating the metal up to a certain temperature, generally before it starts glowing red).

The abrasive disc saw is faster because I can use a jig, so I don't need to measure it every time. There isn't an easy way to do that with bolt cutters.

Post a Comment

<< Home